Desalters / Electrostatic Solutions

TROSEK being an exclusive partner of a US prestigious company in the MENA region, provide quality products and services to our clients.

The DESALTING PROCESS is a series of complicated reactions that at times can be unpredictable and difficult to control not knowing how to mitigate this fact has led to countless revamps, rework, and operating profit loss. There are many contributing factors affecting Stoke’s law other than just gravity, viscosity, temperature, and droplet size. The last of which may constantly be changing in a high-voltage environment.

The effect of emulsifiers can play a large role in how successful or unsuccessful a Desalter may operate. Besides natural emulsifiers like Asphaltenes and Naphthenic acid, there are many other impurities that can be added during production and transportation.

Some of the emulsifiers that can be added during production are; drilling mud additives, fracture fluid additives, corrosion inhibitors, organic acids (acetic), sulfonates and cleaners, pipeline friction control, bacterial products, scale control additives, wax crystal modifiers, etc.

Our services include:

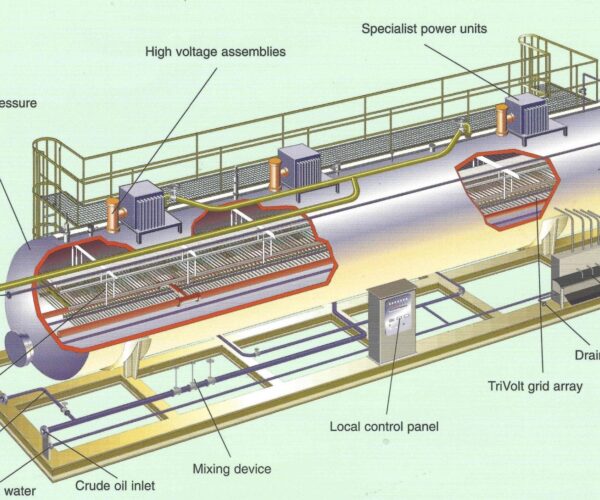

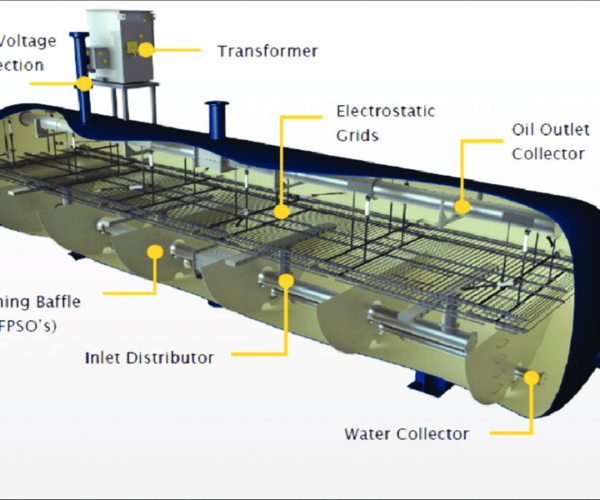

- New Desalters / Retrofit Desalters

- Precipitators

- Dehydrators

- Heater Treaters

Upgrades, Better Replacement Parts, Field Service, Process Optimization, Inspection, and Training.

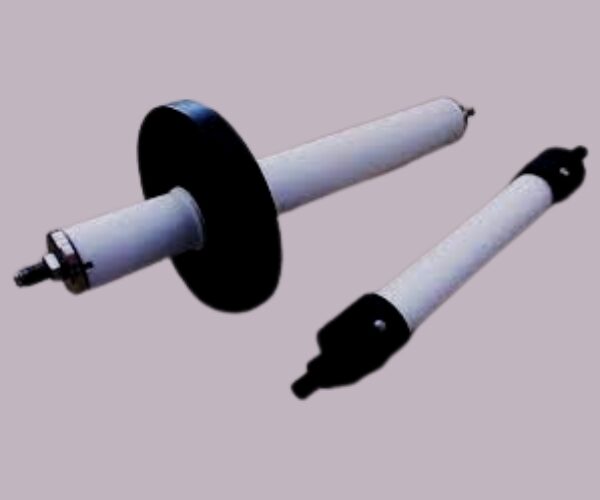

Consumables: Transformers, Grids, Bushings, Sensors, insulators, Mixing valves, etc.

Upgrades: Voltage Controllers and Automated optimization.